Well, one of the big things that happened last month is that I went to England with Misha. It was a short visit (the pictures are linked to a larger version).

On the way up to Mum’s house on the first day, we walked through the farmers market – I got a bit turned around, and didn’t realize which street we were on and assumed it was really small this time of year (above left in front of the only vege stand we found on this street). Above right: “Changed Priorities Ahead” (hopefully they are enjoying themselves more).

We went back to the farmers market with mum – a bit late as everything was getting closed down for the day. We still got some yummy flapjacks, though.

We went on a long hike to the Woolpack (famous because the author Lorrie Lee used to love this pub), had a pint and some “chips”, then continued the hike up Swift hill. On the way up the hill, we came across paintings of badgers in many different costumes on the fence posts. There must have been over thirty paintings. They were painted as part of a protest against the “badger cull“.

The weather was quite warm (for February), but drizzled on the day of our hike. This is the view from the top of Swift hill, looking down over the Stroud valley toward the river Severn (off in the haze somewhere…)

Mum and Misha sitting at the top of Swift hill (just before Misha pulled out some energy bars to share). The snowdrops were all out – couldn’t help trying to catch a photo on the way down (above right).

Here I’m trying to take a selfie with the black sheep. Who isn’t a black sheep in some way?

The flash made their eyes glow. Kinda creepy?

We rented a very little house in Stroud to stay in for the week. Here’s Misha locking the front door. Yes, we did have to duck to walk in. Fortunately, the ceilings were a little higher!

Above left: breakfast! Above right, a photo of Misha, Mia and me from about fifteen years ago. Maybe more.

We also took a trip up to Manchester to visit a family friend (our second mum Jaya, from when we lived in a house filled with eleven children and three single mums). I’d not seen her for over ten years – Misha probably more than 20!

Mum wanted us to break down a brick wall and do some hedge trimming while we were visiting. I refused to climb up a ladder on the sloping driveway to trim branches – so Misha did it!

Above left is a photo outside mum’s house. Above right: Does this product name look appetizing to you (Gü)?

One last photo before we took a train back to London.

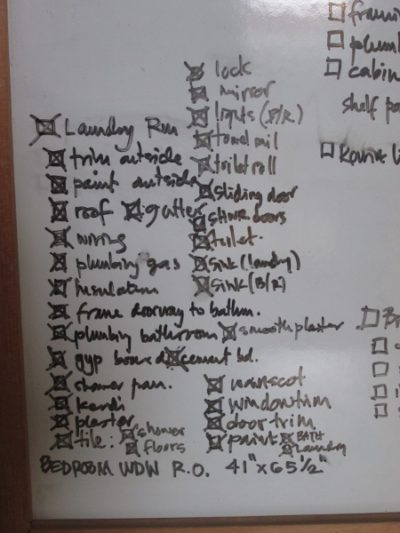

Hmm, so I also did some tile work. Actually, I finally finished the tile on the floor in the laundry room. This is the hexagon tile, with some black tiles used to create patterns. Initially, I was planning to do a border in this room. Then we decided to just do the same patterns as the bathroom, and also something in the middle. And then I added an extra little circle at the center of each wall line. And then (see later)…

Above left, a detail of the pattern in the middle, and above right is one of the only cut edges (at the door).

Above is how I looked all day. My knees hurt.

Above left you can see why there was very little tile cutting. I could just continue the tile under the base boards, and didn’t need to finish them tight against the wall (actually, it’s much better not to, so there’s some expansion room).

It’s hard to see in the photo, but instead of cutting the baseboards both at 45 degrees at the corner, I have butted them together, and hand-cut one of them so that the piece on the left fits into the grooves on the piece on the right. This is the way it was always done before power saws, and actually results in a joint that is less likely to open as the wood expands and contracts. It’s much more work (of course).

Here’s the tile all in, and grouted. When I was installing the tile, I ran out of white tile (about half a square foot short), so tried adding even more patterns at the doorways with black tiles, so that I could stretch the remaining number of white tiles. In the end, I just had to buy more tile. Now it reminds me a bit of how some people’s tattoos look: Lots of different patterns strewn around. I think it’s about as permanent, too, because I can’t see myself wanting to do this again!

Now the baseboards are all in, the floor is done. While I was putting the baseboards in, I stood on pieces of plywood because it’s a bit early to be walking on the tile (needs a week to cure). I’ll start painting next week.

We had a few weeks of reprieve from the El Nino rains, so I rented a jack hammer and broke out more of the concrete in the back yard. Last year, the pear tree did very poorly in the location I’d put it (even though it did gallantly give us some fruit). The poor tree had almost no leaves, and was being crowded out by some aggressively drought tolerant plants. So I decided to move it. Hopefully the move doesn’t kill it, although the previous location would have anyway.

Here’s after the concrete is all out, and I’ve added mulch. The pear tree used to be on the far left of the upper left photo. Now its at the far right of the same photo. More sun and space. Fingers crossed. Above right, you can see what remains of our peach tree after the tree-jumper incident. It blossomed this spring, and is looking very healthy right now, so I think it will recover.

Mole was taking photos, so I think the texture of the pile of broken concrete appealed to her…

Our garden grows nasturtiums!

While I had the jack hammer, I also broke out some of the concrete in the room underneath the laundry room. We’re calling that room the ‘garden room’. I plan to make it into a place to brew beer 😉 But there’s a bunch of plumbing sticking out of the concrete that I need to remove.

We didn’t get many crocuses this year – but here’s one!

Bella sometimes likes to climb inside my shirts (when they are clean)…

This time she fell asleep in it!

Here’s Arwen looking blissful on a blanket that Mole knitted specially for her!