I’m adding the finishing touches to the garden room. There was still some trim around doors, and baseboards to finish.

I really like the curved piece I came up with for the transition from tall baseboards around the foundation wall, to lower ones around the garden room (above).

Now all the trim in the back room is also finished.

I also put some shelves into that space to store things like bottles (this is going to be my brewery room, right?) I added removable fronts on the shelves so I don’t have a disaster of broken glass after the next earthquake, hopefully.

Arwen came down to inspect the garden room while I was working on the cabinet and counter top.

I sanded the old cabinet (from the kitchen on the ‘downstairs’ floor), and painted it.

Arwen likes tools, except power tools.

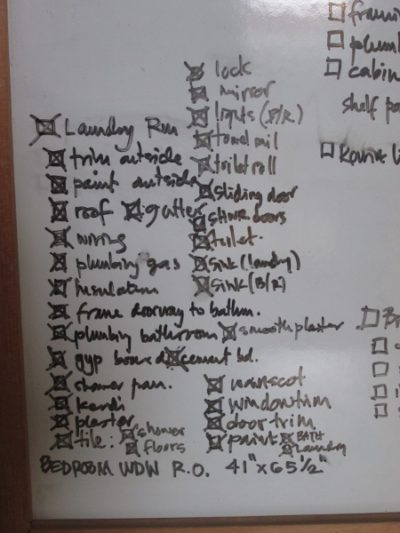

I’ve had trouble with the compression fit piping that’s commonly used under sinks. The plumbing book I have recommends the above alternative. It’s certainly easier to install, and seems quite a bit more sturdy, too.

Here are the cabinets after paint, and new handles. Also, I’ve installed the sink I got from building resources (the local recycler of building materials — construction is responsible for about half of all landfill). I’m going to put the faucet in after the tiling, and a few more coats of polyurethane on the counter.

My godfather sent me a cycling map of San Francisco, and I’ve finally found a good place for it. The garden/brewery room serves mainly as a workout room these days.

Getting started on the tile, I wanted to make it similar to the kitchen in Downton Abbey (white tile with small black squares). The photo above left was the more labor intensive option (I had to cut down the black tiles to about 1.5cm squares). Guess which one we went with.

Here’s the tile after it’s grouted. Not quite as extensive as Downton Abbey, but neither is the brewery room!

I also added a tile backsplash at the little sink in the toilet room.

I had to do some plumbing in the shower upstairs (hair clog!) and the girls both joined in to help:

The Freesia seem to love our back yard: They increase every year (whereas there are only a couple of daffodils left).

This back yard needs some inspiration: Big pile of rocks still there–volunteer Nasturtiums have covered them. Arwen is trying to figure out what to do about it all:

It was a rainy Friday, so Mole’s friday ride group got together to celebrate her birthday. And there was a trip to get vegan donuts, too.

And yesterday Mole’s mum made vegan apple pie for her birthday. It was a triumphant success. Everyone had seconds.

Here are Arwen and Bella pretending to be constellations.