I’m no zen master. For me, the end result is at least as satisfying as the process of getting there. With the house, I often find myself standing staring at some piece of work I’ve finished working on, just enjoying that it’s _done_ (and done right, hopefully).

It took quite a while for the plaque to be made. But I wanted to get a solid brass one, with raised lettering, not the cheap engraved plaques that are easy to make. I like that the cheeky grin remains (caused by rusting of the pin I originally put here).

So here’s some of the satisfaction of a completed project: Our neighbor enjoying the bench in memory of his son.

It’s been quite difficult for me to take a step back and undo a lot of the work I did over the past few years so that I can build the seismic strengthening at the front. This is something that I’d been procrastinating on, and with a comment from an electrician, realized that I needed to stop dancing around the edges and get into it. I put together structural drawings. I got them through the planning and building department. And I even got a bid on it: Wow! More than $0.25 million just for a small portion of it: I guess that means I need to do it.

I built a wall between the work area and the rest of the garage so that bikes would be hidden from view when the garage door is open. I also built a door – but that’s another post (maybe).

The problem I have is that to do this work, I need to tear out the workbench, the electrical work, the gyp board, the plywood – everything. All that satisfaction gone. And then I can get to digging a new foundation, and rebuild everything. Misha came to visit in October and sensed my hesitation so helped me get to tearing things apart.

The old window looking under the stairs. I plan to save this window and reuse it. It’s going to take a lot of repair to make it nice again. But I’ve done it before.

So a major hint that something has gone wrong is that the sill plate on this side of the building has crushed – this has dropped the height on this side of the house by about 2 inches. Maybe rot, maybe something else.

Here is a photo looking at the end of a piece of the wood taken out of the wall here. Any guesses who was living here?

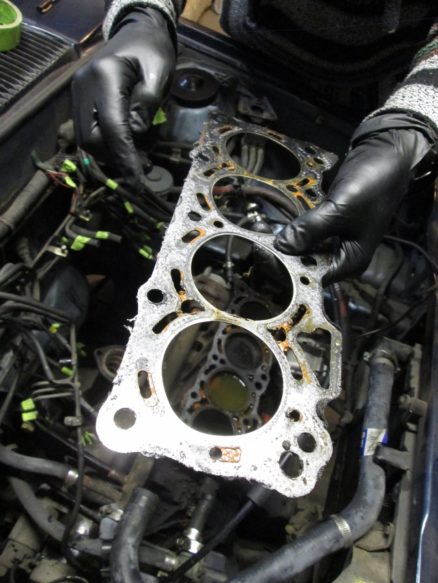

Termites have almost completely eaten the sill plate, and left this behind. We found no termites, so this damage must have happened a long time ago.

It’s always fun to find things in hidden in the walls from a hundred years ago: Japalac (laquer), a picture for Sperry’s flour, someone’s painting of flowers.

And we tore out the gyp board on the ceiling, and the insulation too. Insulation is such nasty stuff – can’t we come up with something that’s not hazardous? We rolled it up tightly and stuffed it in plastic bags for re-use. Whoever did the electrical work really made a mess of these floor joists: It’s not okay to chop into the bottom of joists to fit conduit in there. Bad electrician.

Cleanup time! OK, turtle got a jump start.