Wow, another project that started out as a “quick” project is finished (two years later.) But it came out quite nicely.

A checklist all checked off: satisfying.

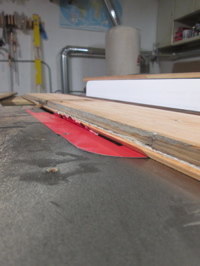

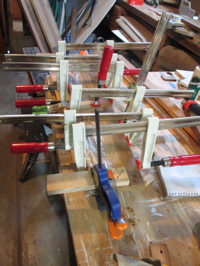

More recycled wood used on the window trim.

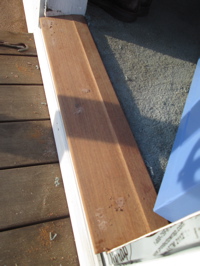

The only problem I had was I bought some different polyurethane by Minwax for the counter top and it’s garbage: It didn’t stick – and I only discovered it when I used tape to mask off the edges while I caulked the joint at the wall. The tape pulled the top layers of polyurethane off the wood! I had sanded between coats, even (and on the can it said that’s not required). Had to sand all the way down to the wood again to get rid of it. I’ll stick with Bona Mega from now on.

Arwen decided she needed to do some inspection when I was plumbing the sink faucet.

Here’s the faucet installed: I offset it to the right slightly, so it’s not in front of the window, and hopefully it makes the sink more convenient for cleaning the large 6.5 gallon carboys. It’s still the brewery room, right?

I also sanded, resized, and stained the old front door (that I’ve had leaning around in our garage for years) to close off the space from the garage. Had to also replace the acrylic glass windows because they were scratched and had been painted over.

Popo left behind a daybed/couch and it has also been sitting in our garage for years. We bought a cheap mattress at Ikea and I put it into the garden room. That’s mole’s bike on the trainer.

… and mole testing it out while I made the living room upstairs stinky (more on that later).

When I first started working on this space, I was thinking of it as potentially a cat-free space for visitors. Little did I realize, but when you live with cats, there’s no such thing as a “cat-free” space: They own the whole house.

Here’s Arwen checking under the day-bed: She’s not happy until she’s checked every square inch.

While mole was riding on the bike trainer, Arwen brought down her favorite wand toy for her.

And Bella just waits patiently on the stairs.

Oh, and here’s the sink in the toilet room, with the tile grouted and finished. Looks neat.

When we moved in (ten years ago!), our plan was to take out the carpets. But we’ve lived with them ever since. I recently decided to take them out: I’m convinced that all that wall-to-wall carpet is not good for air quality. As we took it out, we found that the underlayment had started to decompose, and left sticky red pieces all over the old floor surface, dropping them everywhere as I carried it out: Looked like dried cranberries, but definitely not as good. Lots of work scraping and scrubbing them off.

While tearing out the carpet, Arwen enjoyed the new furniture layout.

This is the old floor tile after we had removed all the old carpet and underlayment, pulled out the staples, scrubbed and cleaned it up and polished the tile. I damaged a lot of it back when I was working on the wiring for the lights downstairs.

So we covered it up with a rug.

This bit was still exposed, though. And Bella did not like it: She started picking at it and broke off part of a tile.

So I decided to replace the broken tiles with some cheap self-adhesive vinyl tile. It was a total pain getting the old tile off (had to use a heat gun). Yes, I’m certain this tile is “hot” (asbestos). Didn’t use protective gear: Hope I don’t regret it. Sometimes I’m just plain stupid lazy. Mole and the cats were downstairs hiding in the garden room.

Done (using the stool my godfather made for me as a weight to glue the corner of an old tile down).

“FEED US! (We are only going to look cute for 30 seconds, then we’re going to melt down and start fighting)”

We got a new rug for the bedroom.

Arwen!

“Helping” with my calculations at the office.

“I’m going to take a nap here, OK?”

Prrrrr…..

Bella loves this box. We stuck eyes on the box – it comes alive when Bella gets inside it. One lesson I learned the hard way: Don’t stand near it – claws will fly out of the corners and grab toes. The robot has lightning-fast reflexes even through its eyes usually get pulled off or rearranged.

The box robot lives!

Nap time.

We volunteered for the AIDS/Lifecycle “day on the ride” in April: It’s a one day test ride for the people planning to do the week-long ride to LA in June. We’re not riding, so it was fun to dress up and help to staff rest stop one.