Haha. Nothing goes quickly. So what’s happened since May? Mark moved out of downstairs, my mum came to visit, we went to visit my brother, I rode my bike a lot, my brother came to visit here, and… I finished the railings on the stairs and deck, and started replacing some of the fence between the deck and the neighbor.

It’s Arwen–wearing her medal: 1st place cuteness.

But before I got to the fence, Mum came to visit. And we went to Taos, NM.

Misha and I managed to get some running in: My knee seems to have healed itself with all the cycling I’ve been doing over the past few years. Before I started cycling, even running to the bus would make my knee swell up the next day.

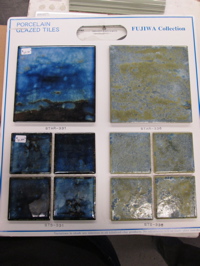

In Taos, we stayed at an ‘earthship.’ The one we stayed at was beautifully decorated with some intricate tile work, and bright, colorful paint. Mum loved it.

We also spent some time in Santa Fe. It was really hot while we were there. I can’t resist taking photos when I see bright colors – this is outside the Museum of Contemporary Native Arts.

And back near home, I went for a walk in Santa Cruz on the beach with both my parents. Haven’t done that in 40+ years!

Oh, and before I get to the house work, I did do a couple of Santa Cruz rides this summer, too. One of them round trip, the second I stayed overnight in Santa Cruz before riding back the next day.

Two sisters and nieces for a Dad’s pre-birthday while my sister was in town.

Oh, and I love this sign:

Lots of bike rides with friends…

Alrighty then: This post was about the railings on the back stairs. We built the stairs years ago, and I never got around to finishing the guard railings. So they were quite dangerous, but we got used to it.

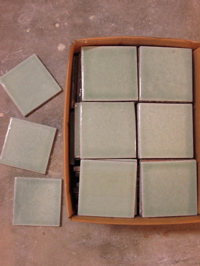

So this summer I finally got around to making the balusters to fill in the railings.

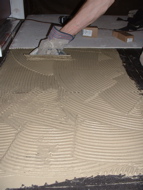

Quite a production effort because there are so many of them. And of course, I’d started making them with a routed detail on the bottom, so that had to continue. On the side of the stairs, the balusters have to be spaced away from the side of the stair stringer. Whenever wood is held tightly together, it stays wet in the joint, so that’s where the rot starts. So I figured I’d fill the gap with waterproof glue: I glued and clamped spacers on all of the balusters.

Here are about half of them when I was staining them:

Mole and Arwen: The railing and balusters at the top landing are all white, because I made those balusters back when we built the stair. At the time I’d planned to paint all of them white.

Here I’ve got balusters on one side of the stair:

Both sides done:

The finishing touch is I added an Ipe plank on top of the railing. It strengthens the rail, but it also looks better I think.

The next project is the fence. It’s very rotten, plus my neighbor doesn’t walk their dog: He just goes out back to do his business. Sad and stinky.

When I took down the old fence, this is what their deck looked like: Utterly insect infested and rotten through. I added some temporary shoring under there so it doesn’t collapse while I’m working, and warned him.

I had to take down my stairs at the bottom to replace the fence. Arwen figured out how to climb up and down the ladder quite quickly. Also, I decided to change the stairs so that they are slightly steeper: This will make it so that there will be more head room at the bottom of the stairs.

Even though I was just changing the stairs slightly and then re-painting, it took a really long time. Stairs are painstaking work because they have to be very accurate. Any unevenness can be a trip/fall hazard.

Oh, and to add another wrinkle, the drain pipe was in the way of the old fence. Rather than build the fence around it, I decided to move the pipe over. Which which meant I had to break out out more concrete: The ever expanding project.

While I had the jackhammer, I decided to expand the bed for the rose bush. This was waaay more work than I’d bargained for, because there was an old concrete footing there, full of rebar. Really hard to break up. Before on the left, six hours later on the right.

At the deck level, I built the wall up tall enough that we can’t see over to the neighbor’s side. If the stink still comes wafting over, I’ll put windows up at the top. Still need to add the finishes to make it look more like a fence, but the wall part is done:

I think mole snapped this photo of Arwen while mole was riding zwift in the garden room. It’s a bit worrying riding on the trainer with the cats in the room: There’s a fast spinning back wheel that could really hurt them. We don’t usually let them in, but sometimes they insist.

Oh, we had a party: Mark, who’s lived downstairs for about five years, is going to Lithuania. So we had a big leaving party/birthday party for him. We strung lights up in the back yard, and it was a great time.

We put a Lithuanian flag out front, too!

On hot days, Arwen and Bella stretch out to try not to over heat. Looks like they are flying:

Mole and I stopped in at Davenport on the way down to Santa Cruz for dad’s birthday; wandered around a little. I guess you can have great views even when not riding a bike:

Bella says: “why are all your photos of Arwen?”

Ooops, one more Arwen photo.

While the Arborist was here, he planted a new Espalier apple tree where we used to have the Avocado. It’s a funny looking tree right now, because it’s been carefully pruned so that it grows horizontally and flat.

While the Arborist was here, he planted a new Espalier apple tree where we used to have the Avocado. It’s a funny looking tree right now, because it’s been carefully pruned so that it grows horizontally and flat.