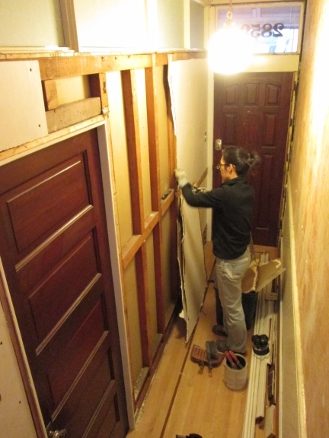

Even though I haven’t posted about it for months, the hallway does continue to progress…

The quarter inch thick drywall on the hallway wall had been exposed to years of moisture from a leaky roof before we bought the house. Years ago when we were stripping wallpaper, the smell of mold established that this drywall should be replaced, rather than plastered over.

Well, now’s the time: Here’s Mole pulling it off the wall. It came down shockingly easily; it had been nailed up with the wrong type of nails, so they just pulled through the drywall.

The wall framing under the drywall is a mess of different sized pieces, some not even nailed in place properly. No wonder this wall rattled in tune to music in peoples cars in the street. I had to plane the wood flat on lots of the studs to make sure the new drywall lays flat; Also added some screws to hold things together a bit better.

I finished up connecting the utilities in the hallway wall. It turned out to be quite a lot jammed into that tight space: Drain for sink, conduit for network cables, and a hot water return. Also wiring for a plug and light switch.

Mole caught a photo of me as I was finalizing the stairs.

Here’s the new drywall going up, to flush out the corner. It’s starting to come together.

The leaky roof also damaged the plaster in the ceiling. Here I’m adding plaster washers to hold it all in place, rather than replace the ceiling.

This is the edge of the ceiling, where it transitions to vertical wall. I’ve filled up to the dowel on one side with joint compound. I prefer to use joint compound on ceilings than plaster, because it doesn’t need to resist bumps and scratches like walls, and it’s easy to sand flat.

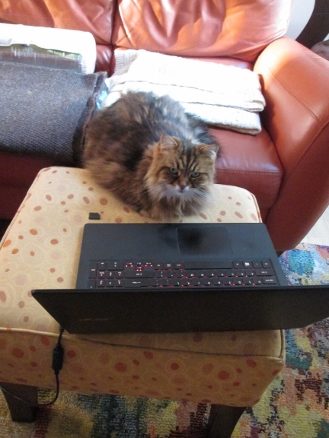

Here’s the ceiling after a couple of passes with joint compound. I haven’t sanded it yet. Probably needs one more pass before sanding. Now I need to go find some cat photos…