as active as our social lives have become, mathew still manages to get A LOT done on the house. i’m just a little slow at posting. maybe we should change the blog to “SuperTurtle+snail”…

on a warm morning i helped mathew with masking of the wood trim using paper, tape and plastic.

the room ready for painting. after all the masking was done i think it took mathew about 30 minutes to paint with the electric paint sprayer and about 3 hours to clean the silly machine.

now with the primer on the walls we were ready to start trying out colors. since this will be my office mathew wanted to paint it my favorite color, a medium blue-purple which i often call “blurple.” the large swatch proved to be too much for the entire room. (the colors are not showing up correctly in these photographs, it’s a fairly bright periwinkle but my photos look more like a medium cornflower…)

we decided to choose a warm ‘elephant grey’ for the room and the ‘blurple’ for two accent walls, where my desk will go and above the mantle.

i’m not sure if i even like this… i find it ironic that friends ‘hire’ me to choose colors for their homes and businesses but i can’t even choose colors for myself!

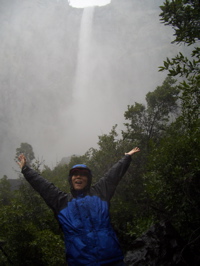

the skylight saga continues..! so you may remember back in april we hired roofers to re-do our roof and put in a new skylight. they completed the roof but completely messed up in installing the skylight, they even threw out installation parts! so two months later, after the drama of not being able to replace the parts, they returned to finish the job. just to make sure things were done correctly, mathew took the morning off work to supervise and even help with some of the work. i think they found him helpful, he thinks they found him annoying. (above) here he is happy that it’s finally done and making some adjustments to things that were still done incorrectly.

later that day he came home from work excited to finish the interior details of the skylight. (above left) cutting and installing gypboard to fit the curves above and below the skylight. (above right) not sure if you can see, but our friend mike is here visiting and mathew is STILL working.

after a late night and a fairly early morning, mike heads off to watch the world cup with their mutual friends while mathew stays to complete the skylight. (left) he bought this rigid plastic corner reinforcement and is cutting it to fit curves.

(left) installing the corner reinforcement. (right) applying plaster.

the skylight after a few coats of plaster. it still needs sanding and painting but it looks pretty amazing and very professional.

here’s the finished skylight after more plaster, sanding and paint.

mathew is very happy with how this turned out. he likes the modern, contrasting curves of the ceiling, sloping wall and skylight opening. i love that this project is where we have all of our meals so mathew can sit and enjoy his work every day. (above left to right) top and bottom details.

but wait there’s more!

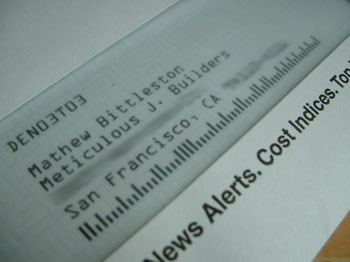

mathew ordered new wood windows for my office. they are double paned, argon filled with a low-e coating. this means they are going to insulate against heat, cold, sound (neighbors!), and protect against the sun fading things when the sun streams in in the afternoons. it also means they’re expensive! (left) here mathew is fitting the top piece into the left window frame. (right) because this house is old and has done some settling, the windows aren’t totally square. here mathew is down in the garage planing the lower piece to fit.

after all the side windows have been adjusted to fit and sanded until incredibly smooth…

(left) staining and polyurethaning of the insides happens, (right) and priming the outsides after that.

unfortunately there was a mistake in the ordering of the larger middle window, the lower piece was made with only a single pane of glass, so that window will have to wait. these windows are custom built and may take another two months to receive the correct window… no worries, there’s always other stuff to work on!